PLASTIC BOILER

Plastic boiler making requires a very technical know-how:

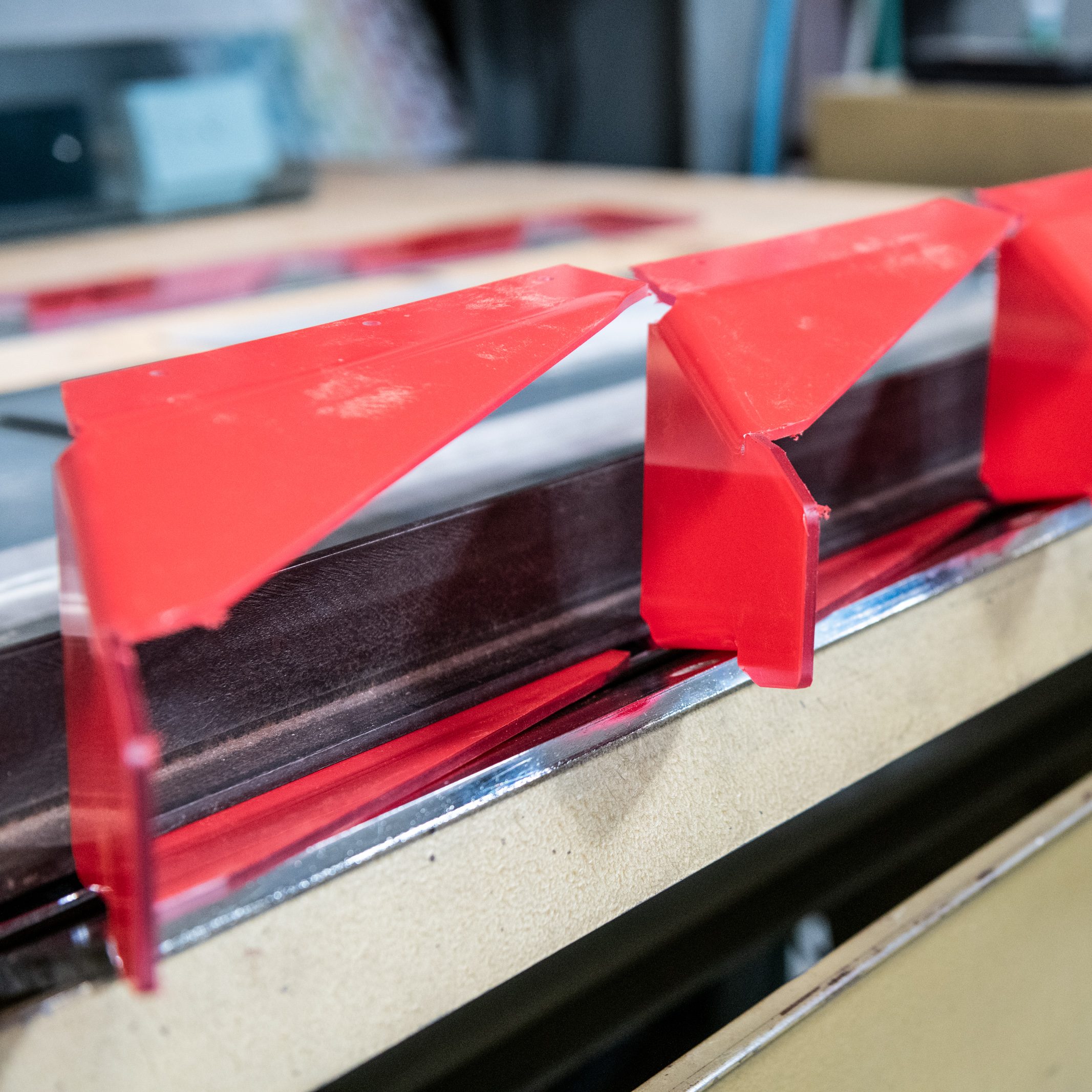

- Hot bending, plastic welding, UV gluing, silicone, engraving, marking.

Thermoplastics products have a number of different application:

- Capsizing, protection components ;

- Transparent or opaque protective cap, custom-made technical bags ;

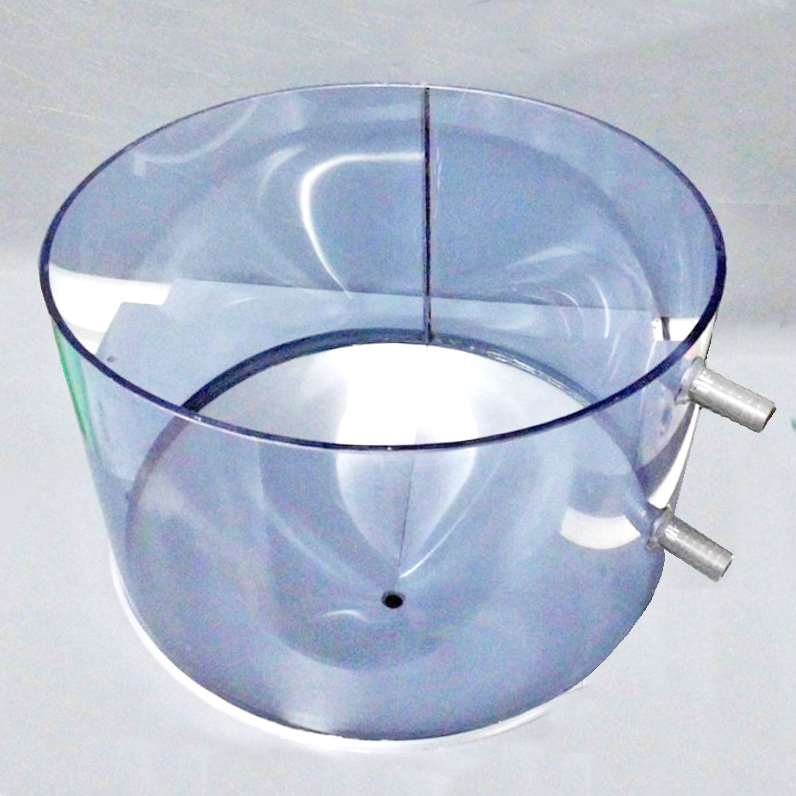

- Retention bin, tanks, food distributor ;

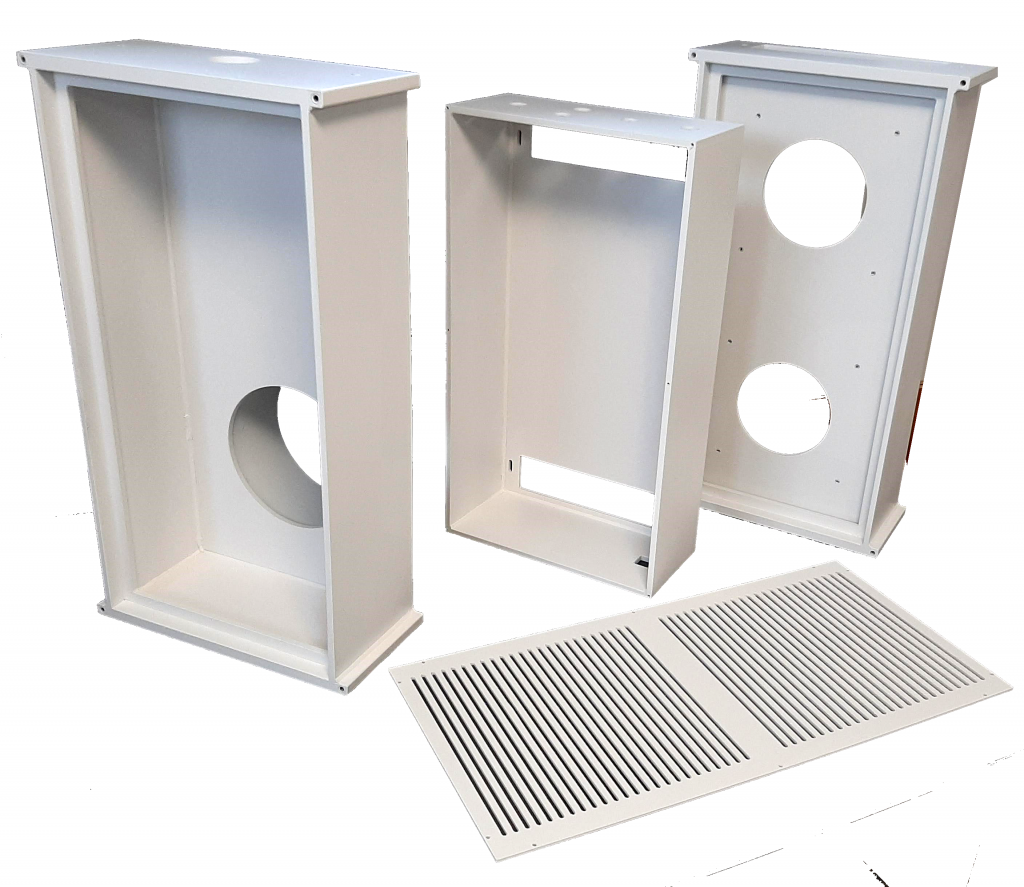

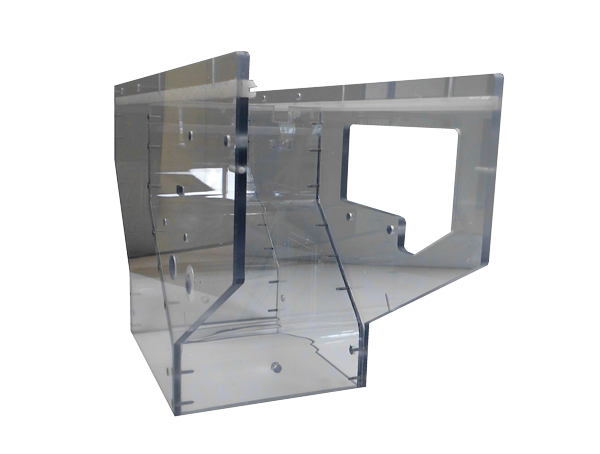

- Technical cabinet, boxes, cases, safe ;

- Transparent or opaque laboratory equipment ;

- Mechanical components.

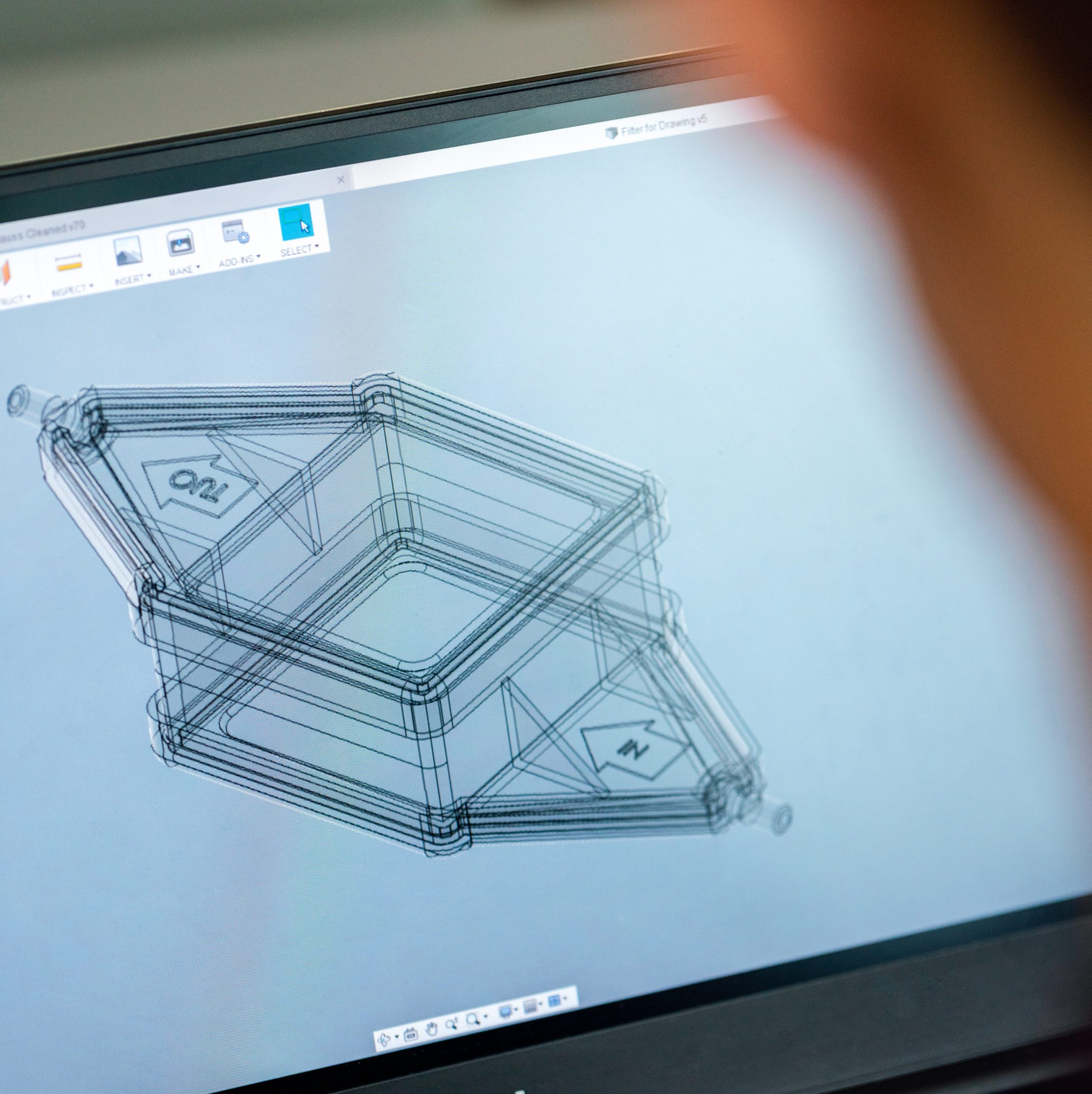

Once we receive your plan, we are executing an optimization process in order to realize your part:

CAO – Carrying out the program for machining CN

GABARIT – We are producing template in wood and/or in plastic for the moulding

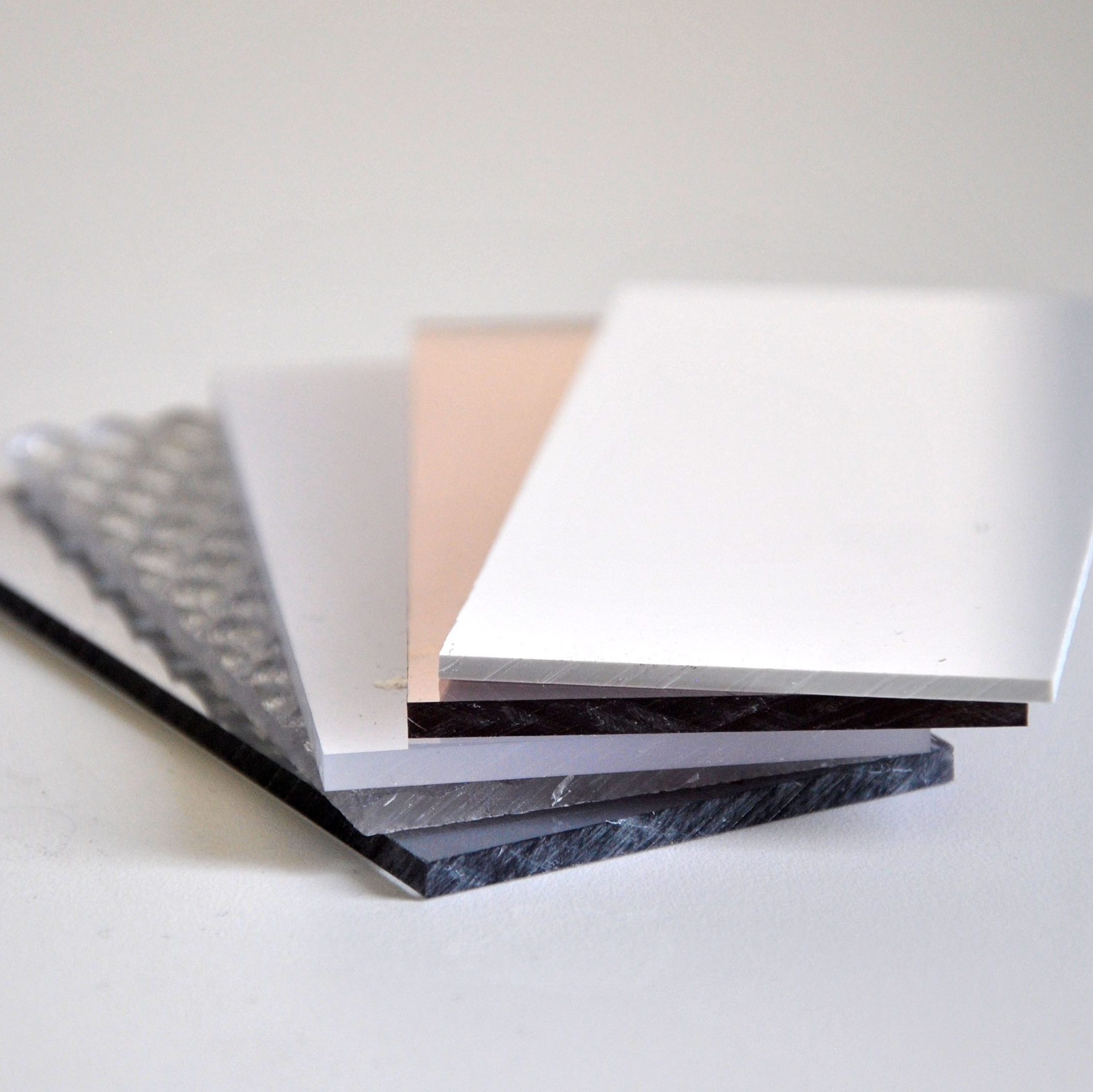

SELECT MATERIAL – Our trained teams help you to select the most suitable material (process, temperature, atmosphere)

MANUFACTURING PROCESS – By machining material on a numeric pad ripper or by hot forming in a heat proofer.

ASSEMBLING – Cutting, hot bending, drilling, re-machining, polishing, collage, screwing, welding, assembling subset.

DELIVERY – Immediate shipment, thanks to our carrier network we offer very good delays at the end of the production everywhere in France and abroad.

EXAMPLES OF REALIZATIONS

ICM Industrie will accompany you to select your material and then from the conception to the fabrication of your prototype including the qualification, for medium and big series.